Navigating the World of Fasteners and Machining: Approaches for Precision and Rate

In the elaborate realm of fasteners and machining, the pursuit for precision and speed is a continuous difficulty that demands meticulous interest to detail and tactical preparation. From recognizing the diverse array of bolt kinds to picking optimal products that can endure rigorous needs, each action in the procedure plays a pivotal duty in attaining the preferred outcome. Accuracy machining strategies further boost the complexity of this craft, needing a delicate equilibrium in between technical know-how and ingenious approaches. As we look into the approaches that can enhance both rate and effectiveness in this domain name, the interaction between quality assurance procedures and operational excellence becomes an essential centerpiece.

Understanding Fastener Kind

When selecting fasteners for a job, comprehending the numerous kinds readily available is important for making certain optimum efficiency and dependability. Bolts are made use of with nuts to hold materials with each other, while screws are functional bolts that can be made use of with or without a nut, depending on the application. Washers are necessary for dispersing the load of the bolt and preventing damages to the product being attached.

Choosing the Right Products

Comprehending the significance of selecting the ideal products is vital in making sure the optimal efficiency and reliability of the chosen fastener kinds talked about previously. When it pertains to bolts and machining applications, the material choice plays a crucial function in figuring out the overall stamina, durability, rust resistance, and compatibility with the designated setting. Various materials use varying homes that can significantly affect the performance of the fasteners.

Common materials utilized for fasteners include steel, stainless steel, light weight aluminum, brass, and titanium, each having its one-of-a-kind strengths and weaknesses. Steel is renowned for its high toughness and toughness, making it suitable for a variety of applications. Stainless steel supplies exceptional corrosion resistance, ideal for environments susceptible to moisture and chemicals. Light weight aluminum is light-weight and corrosion-resistant, making it suitable for applications where weight decrease is crucial. Brass is often chosen for its visual appeal and superb conductivity. Titanium is known for its extraordinary strength-to-weight ratio, making it suitable for high-performance applications. Picking the right product includes thinking about factors such as stamina demands, environmental problems, and budget plan constraints to ensure the wanted performance and long life of the fasteners.

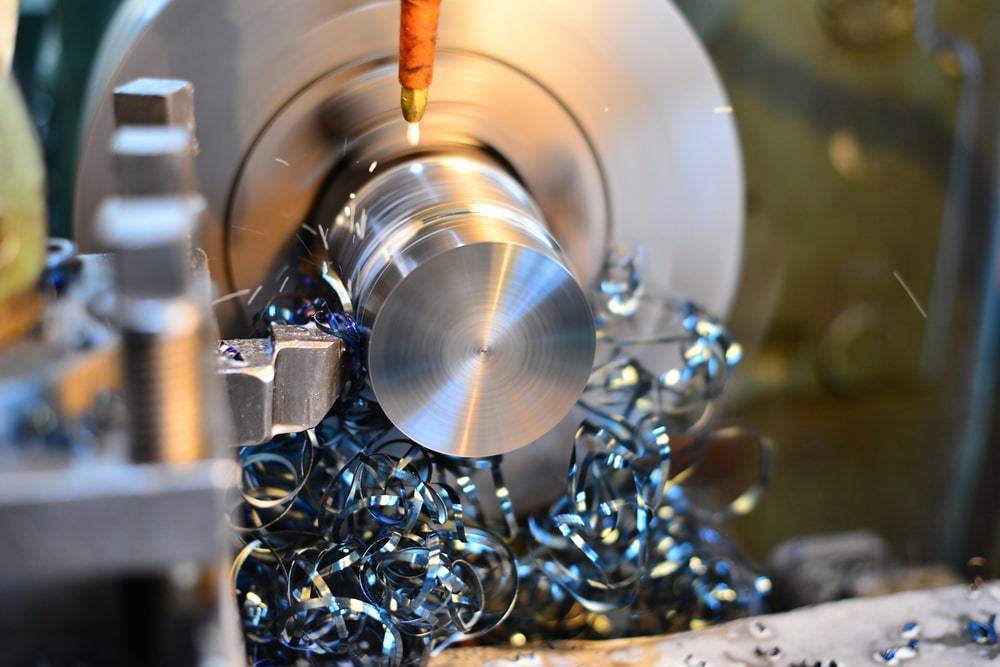

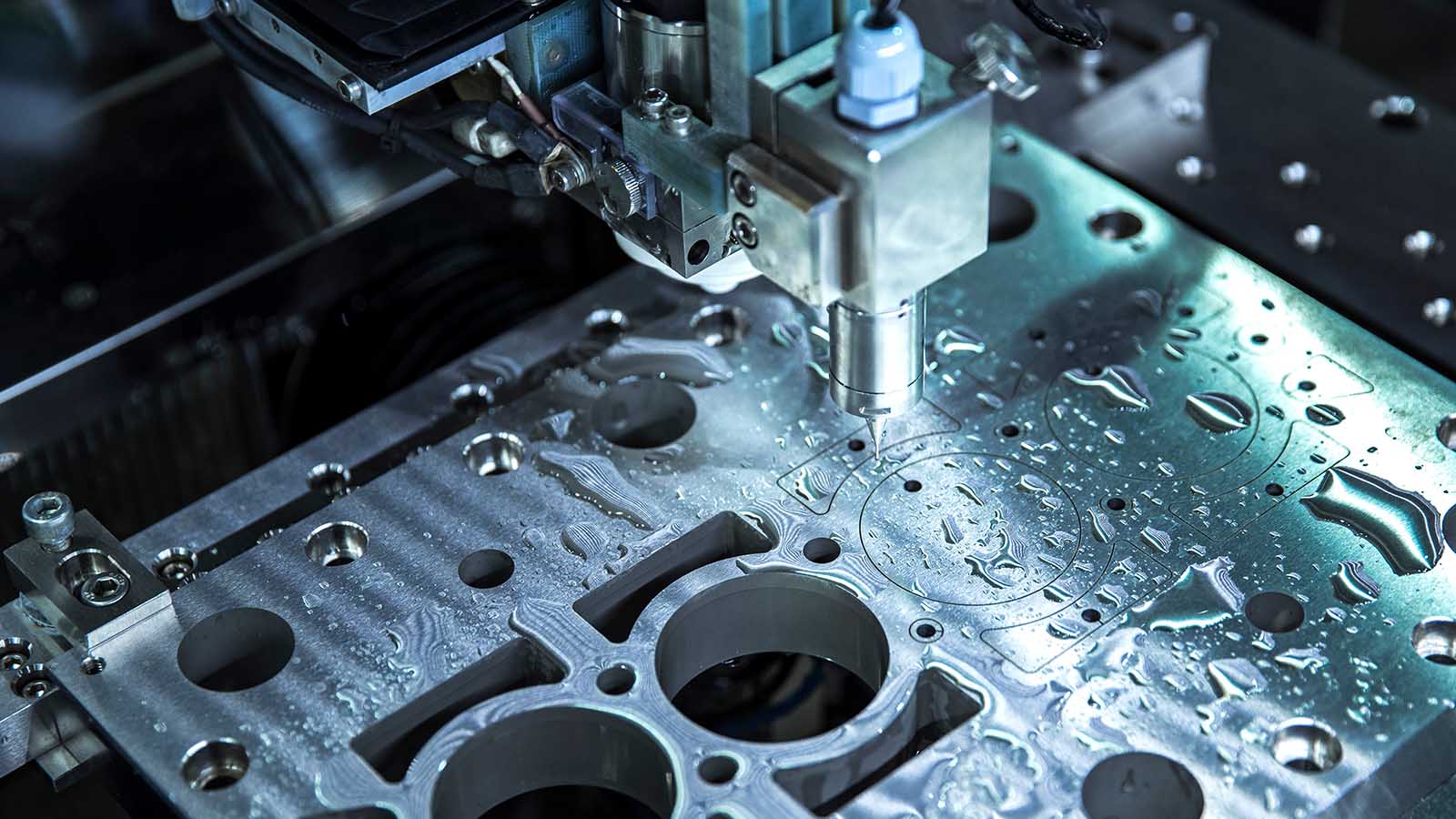

Accuracy Machining Techniques

In addition to CNC machining, other accuracy techniques like grinding, turning, milling, and exploration play crucial roles in fastener manufacturing. Grinding helps achieve great surface coatings and limited dimensional resistances, while site link transforming is often used to develop cylindrical parts with accurate sizes. Milling and exploration operations are crucial for shaping and creating holes in fasteners, ensuring they satisfy precise specifications and function properly.

Enhancing Speed and Performance

To maximize fastener production processes, it is vital to streamline operations and implement efficient methods that match accuracy machining methods. Automated systems can manage repeated tasks with accuracy and speed, permitting employees to focus on even more complex and value-added activities. By combining these methods, producers can achieve a balance between speed and accuracy, ultimately improving their you can find out more affordable edge in the bolt industry.

Top Quality Control Procedures

Carrying out strenuous quality assurance actions is critical in making sure the dependability and consistency of bolt products in the manufacturing process. Quality assurance steps include numerous stages, beginning from the option of resources to the last evaluation of the completed bolts. One fundamental element of top quality control is performing extensive material assessments to confirm compliance with specifications. This includes assessing aspects such as material strength, structure, and sturdiness to guarantee that the fasteners satisfy sector criteria. Additionally, monitoring the machining processes is important to support dimensional precision and surface coating high quality. Using sophisticated innovation, such as automated inspection systems and precision measuring devices, can enhance the precision and efficiency of high quality control treatments.

Normal calibration of equipment and equipment is vital to keep consistency in manufacturing and guarantee that bolts meet the necessary resistances. Applying rigorous procedures for recognizing and addressing non-conformities or flaws is crucial in stopping substandard products from entering the marketplace. By establishing a thorough top quality control framework, producers can support the reputation of their brand name and supply fasteners that meet the greatest criteria of performance and sturdiness.

Final Thought

In the elaborate realm of fasteners and machining, the quest for precision and speed is a continuous obstacle that requires precise attention to information and tactical planning. When it comes to fasteners and machining applications, the material option plays an important function in figuring out the overall stamina, longevity, deterioration resistance, and compatibility with the designated atmosphere. Accuracy machining involves numerous innovative methods that make sure the limited tolerances and requirements required for fasteners.In addition to CNC machining, other accuracy techniques like grinding, transforming, milling, and drilling play crucial roles in fastener manufacturing.To maximize bolt manufacturing processes, it is essential to streamline procedures and execute reliable approaches that complement accuracy machining techniques.